Steam turbine high temperature casing cracking

Dispatching requirements for many combined cycle plants (CCP) have pushed design limits for fast starts, load and on-off cycling operations.

Dispatching requirements for many combined cycle plants (CCP) have pushed design limits for fast starts, load and on-off cycling operations.

Based on a recent assessment of nuclear and fossil generating stations in Europe, TG Advisers identified various levels of torsional vibration concerns in more than 25 units.

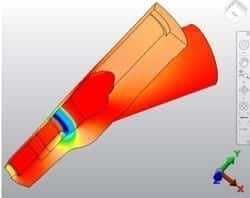

Control and governor valves operate under severe service conditions. Exposure to high temperatures, erosion, water induction and low- and high-cycle fatigue can significantly reduce valve life.

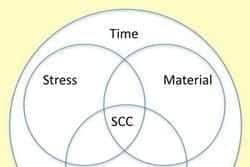

Stress corrosion cracking (SCC) of low-pressure steam turbine rotor blade attachments is an industry issue on older fossil and nuclear units.

Combined cycles are expected to cycle on and off more frequently than conventional fossil-fired units.

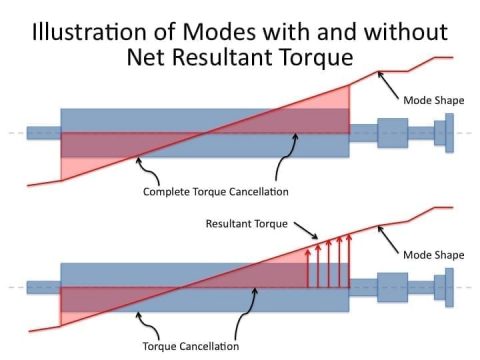

Torsional vibration resonance can result in significant turbine and generator damage and extended forced outages.

Combustion turbine blade maintenance and refurbishment intervals must take into account many design and operation specific factors

Gas turbine hot-section hardware requires part refurbishment after a specified number of operating hours, unit stop-start cycles, or a combination of the two.

Background Reducing the minimum load at which a unit can reliably operate is one method to increase revenue potential during lower demand periods. For this reason, it is not unusual to see merchant plants operating at super minimum load levels well below 25% rated full load. However, these units are operating well outside the original […]

Background In the early 1970’s, the industry experienced a number of unsolved low-pressure turbine blade failures. The most notable occurred at the Prairie Island Nuclear plant with repeated failures of the last few rotating rows. Exhaustive analysis and strain gauge testing revealed the blades were responding to steady torsional excitation from the generator created by […]

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

We are steam and gas turbine – generator and utility plant experts providing engineering consulting services to the power industry.